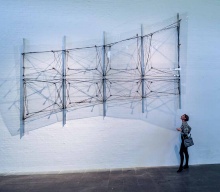

Fibre Facade Prototype

The Fibre Facade Prototype is a new building component demonstrator created for the Innochain Network Exhibition “Practice Futures: Building Design for a New Material Age” which opened on the 31st of August at KADK in Copenhagen, Denmark.

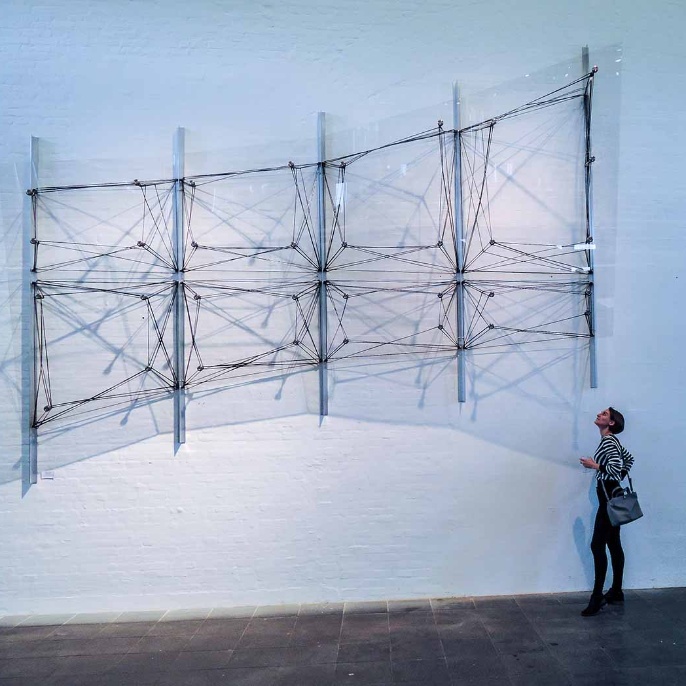

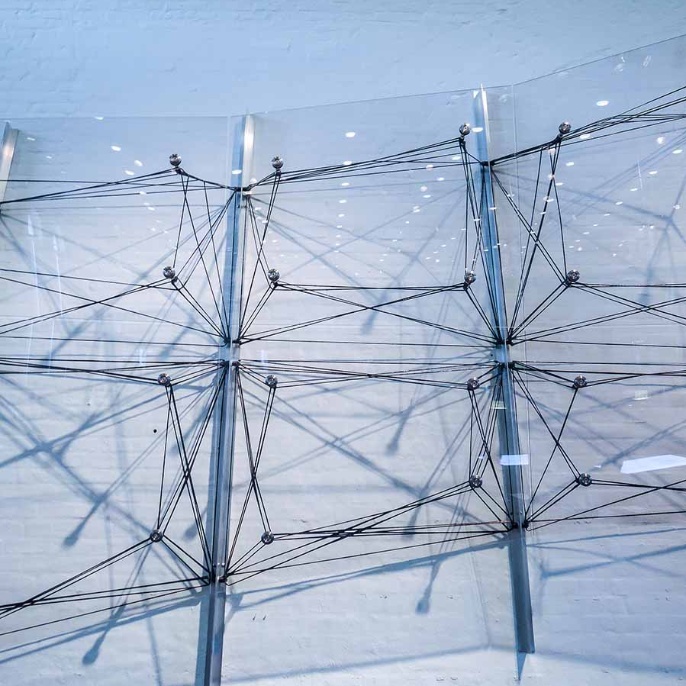

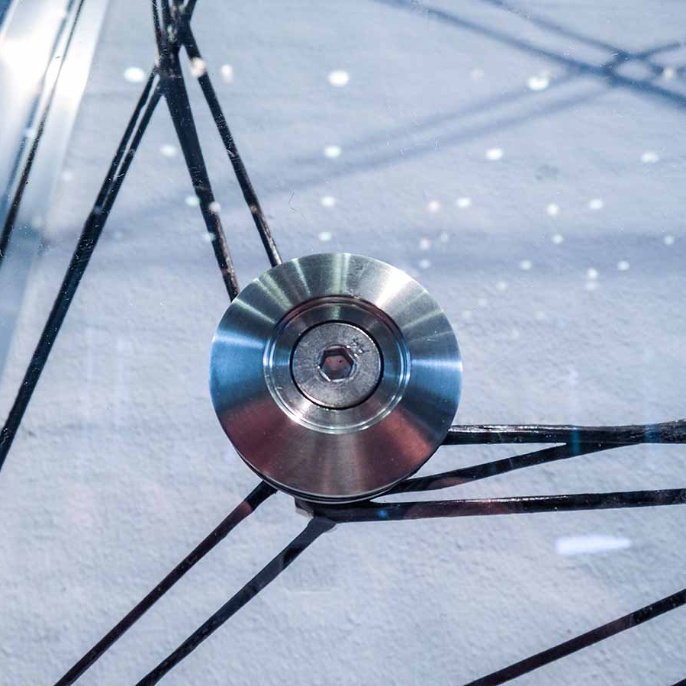

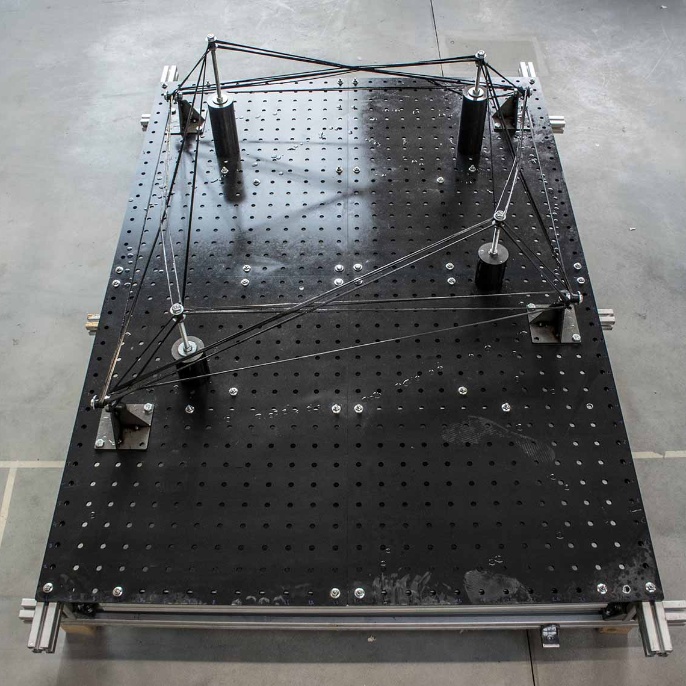

The prototype was developed in collaboration between the ITKE, University of Stuttgart and FibR GmbH as the final product of their Innochain Industry Partnership. It consists of eight unique CFRP (carbon fibre reinforced polymer) frames that were fabricated by coreless filament winding and support eight planar polycarbonate panes in unique positions and orientations.

Coreless Filament Winding is a fabrication process developed by the University of Stuttgart since 2013 and involves the winding of pre-impregnated, uncured fibre tows around a minimal scaffold. The composite is then cured and the scaffold removed to leave a rigid composite lattice component. The majority of structures fabricated with this method to date (ITKE Research Pavilions 2012, 2013-14, 2016-17 and Elytra Filament Pavilion) have been surface/shell structures with a closely wound lattice form where gaps between fibre crossings are less than 50mm.

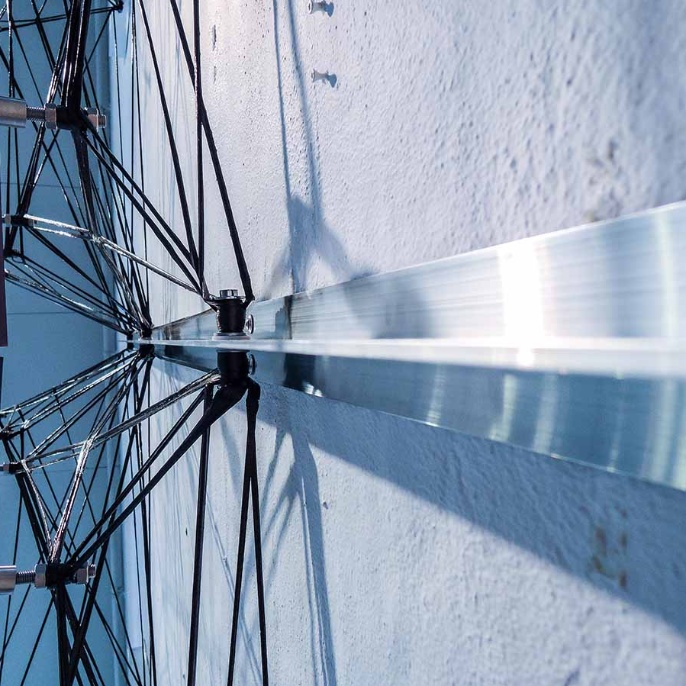

In comparison to these, the Fibre Facade demonstrates the possibility for the general concept behind coreless filament winding to be used effectively on truss-type structures, where cured filament bundles act as struts within a carbon fibre framework. The strength of the composite is visually demonstrated by using the minimum amount of material to support the facade panes and the flexibility of coreless filament winding is shown by the creation of the unique parts with a common reconfigurable scaffold system, simply adjusted to suit each piece.

The cfrp frames are designed to carry glass panels and the expected wind loads for a typical building envelope.The heaviest frame weighs only 990g and the combined mass of all eight carbon fibre parts is just 4.2kg. They support 8.75m2 of polycarbonate cladding weighing 90kg in the exhibition and were designed to carry twice that mass in glass.

Project Team

ITKE – Institute of Building Structures and Structural Design – Prof. Jan Knippers

Concept, Scientific Development and Engineering: James Solly (Innochain ESR 08)

FibR GmbH, Stuttgart

Design Development, Fabrication: Moritz Dӧrstelmann, Teodor Andonov

Acknowledgements

This project received funding from the European Union’s Horizon 2020 research and

innovation program under the Marie Sklodowska-Curie grant agreement No 642877.

The project CFRP material was kindly provided by FibR GmbH

The project facade fixings were kindly sponsored by Pauli+Sohn GmbH.