glasstec 2014

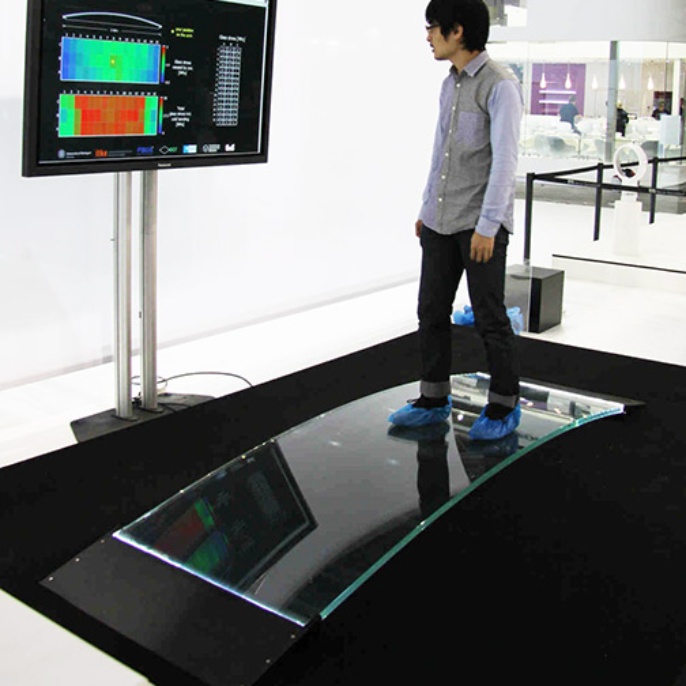

Presentation of a sensitive arch from cold bent glass with integrated fibre-optical sensors for stress sensing at the glass technology live exhibition as part of the glasstec 2014 trade fair in Duesseldorf, hall 11 at the trade faire exhibition area.

Description

Glass products for application in buildings and vehicles are often designed as laminates for safety reasons and for structural use. The stiffness and the structural behaviour of such glass laminates mainly depends on the applied glass types (annealed or tempered glass) and interlayer properties (e.g. PVB, EVA, PU or ionomers).

For glass applications requiring smooth, low curvature and high optical surface quality, cold, elastically bent glass with shape stabilisation through lamination is increasingly used. Depending on the glass thickness, minimal curvature radii of 3-4m can be achieved with fully toughened glass (FTG).

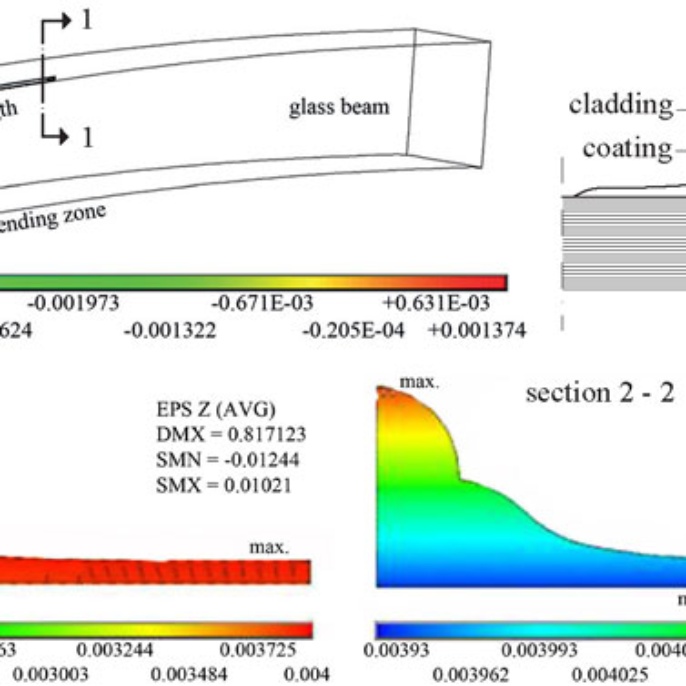

Conservation of the curved shape is possible through lamination of several cold bent glass layers with shear-stiff polymer interlayers. So, the curvature is permanently maintained without fi xing on a substructure. However, as the stress from cold bending remains in the glass, monitoring solutions for the short- and long term behaviour of such curved and planar glass laminates are necessary.

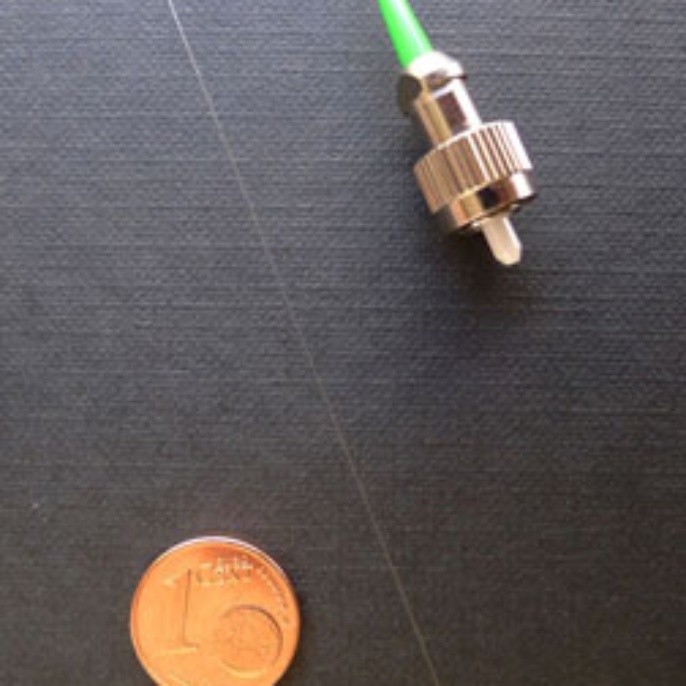

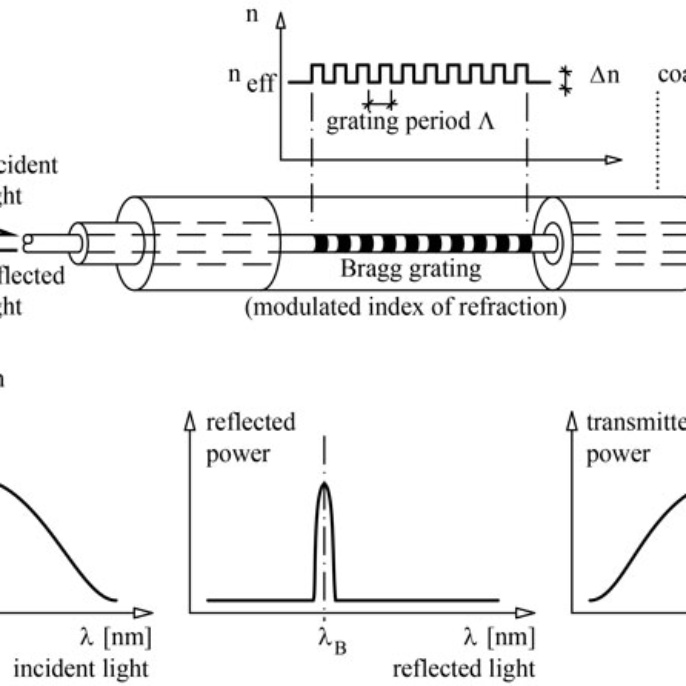

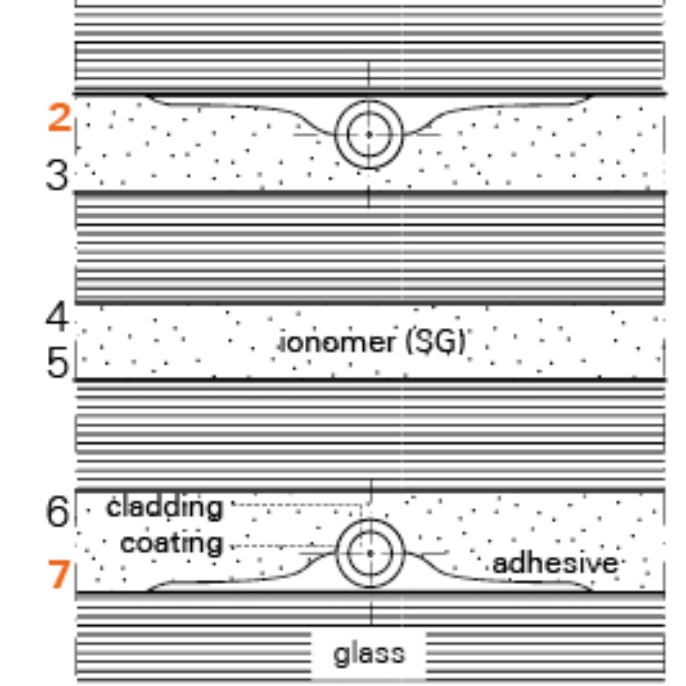

A new approach developed at the ITKE therefore deploys thin, barely visible fi bre-optical sensors for the fi rst time to permanently measure stress and temperature inside of glass laminates. Fused silica waveguides (d=0.125 to 0.195mm) with Bragg-gratings are applied. These gratings consist of a periodical modulation of the refractive index of the fi bre generated by UVlaser beams. Strain sensing is based on the measurement of characteristic spectra (1500-1600nm) of laser light passing the waveguide being refl ected at the gratings. Mechanically or temperature induced strain in the fi bre causes a measurable shift of the refl ected spectra, which is used to determine the related stress.

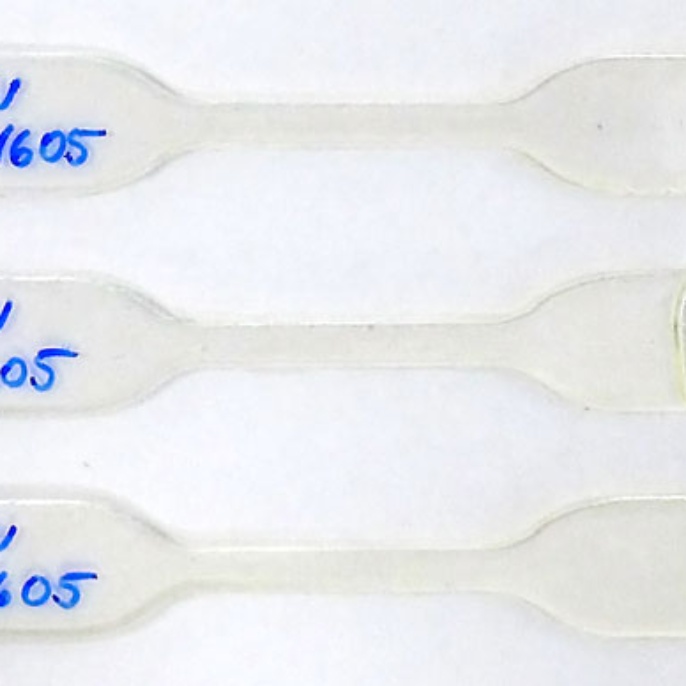

In collaboration with industry and research partners, a transparent load transfer connection of the sensors through UV-curing adhesives has been developed and tested on planar and curved glass. The fi bre-optic sensors based on Bragg gratings proved to both withstand the lamination process in an autoclave (140°C and 13bar pressure) and to monitor long-term stress in the laminates.

The fi bre-optic sensor technology with Bragg gratings principally proved to both withstand the lamination process of glass products and to perform long-term stress and temperature monitoring in the laminates during manufacturing and later application.

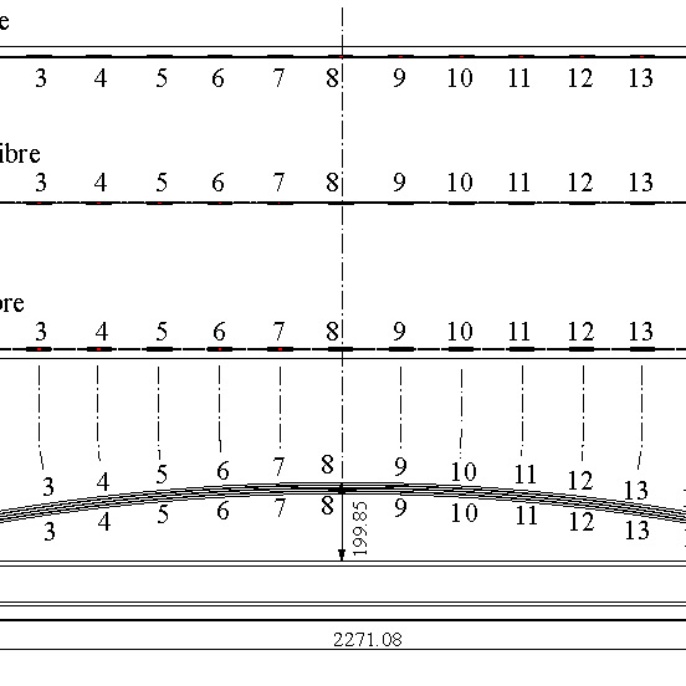

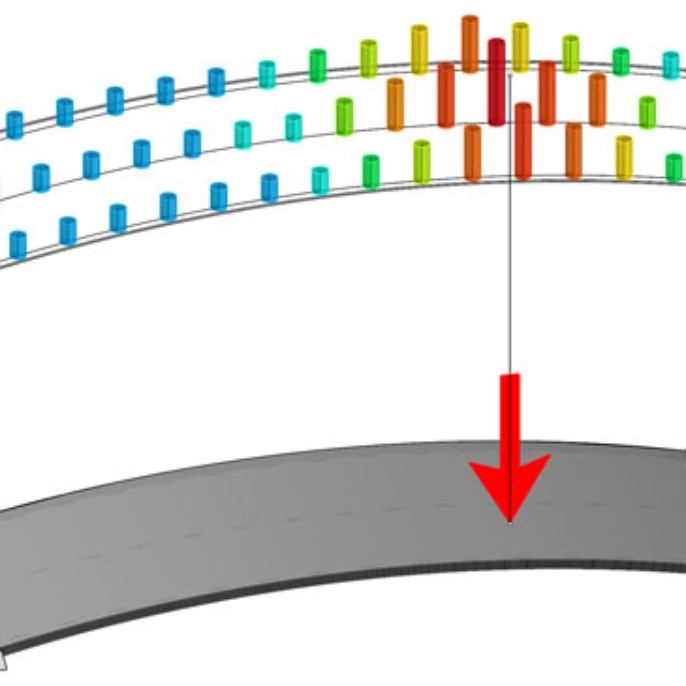

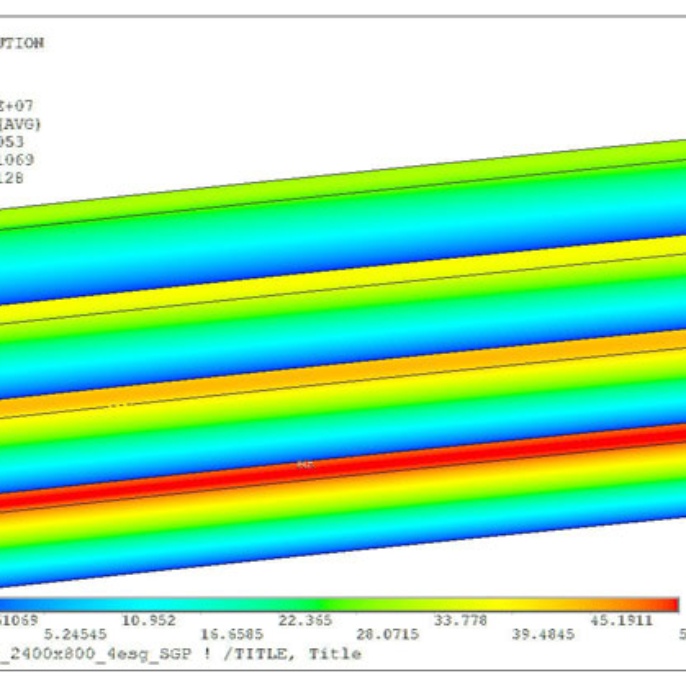

Possible applications of fi bre-optical sensors in glass laminates are presented at the glasstec 2014 by means of a cold bent glass arch (l=2.4m, b=0.8m) from 4x6mm FTG (BI-Tensit by BGT / INGLAS) laminated with 1.52mm ionomer interlayers. The position of a person crossing the arch is determined through a network of 90 fi bre-optical Bragg sensors (DTG-A3A4 with Ormocer®-Coating, by FBGS).Furthermore, the glass stress caused by the person´s weight and the permanent stress from cold bending are measured and visualised in real-time (optical strain analysis device FBGScan 804D from FBGS providing a 500Hz signal rate).

Project Management:

Institute of Building Structures and Structural Design, Universty of Stuttgart

Prof. Dr.-Ing. Jan Knippers, Dipl.-Ing. Thiemo Fildhuth

Project Partners:

BGT Bischoff Glastechnik AG, Bretten

FBGS Technologies GmbH, Jena

GuS – Präzision in Kunststoff, Glas und Optik GmbH & Co. KG, Lübbecke

INGLAS Produktions GmbH, Friedrichshafen

Technische Universität Dresden, Institut für Baukonstruktion, Dresden