Textile Hybrid M1

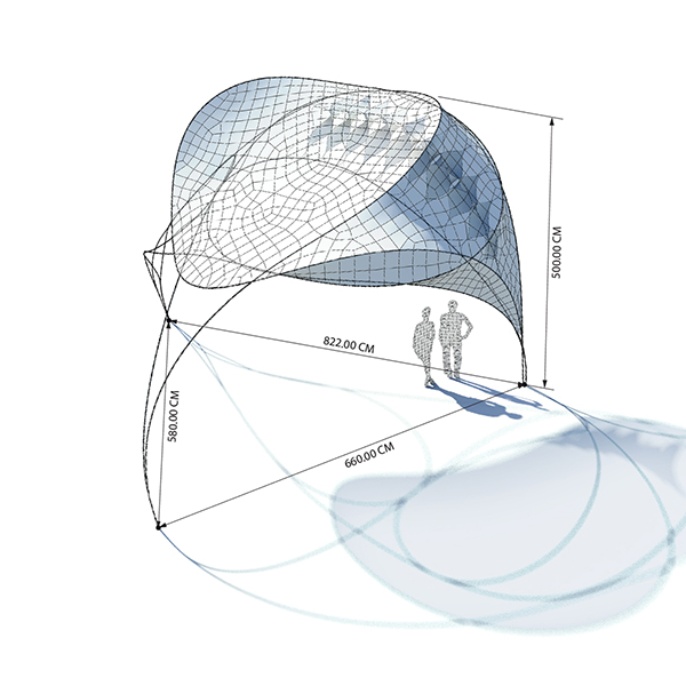

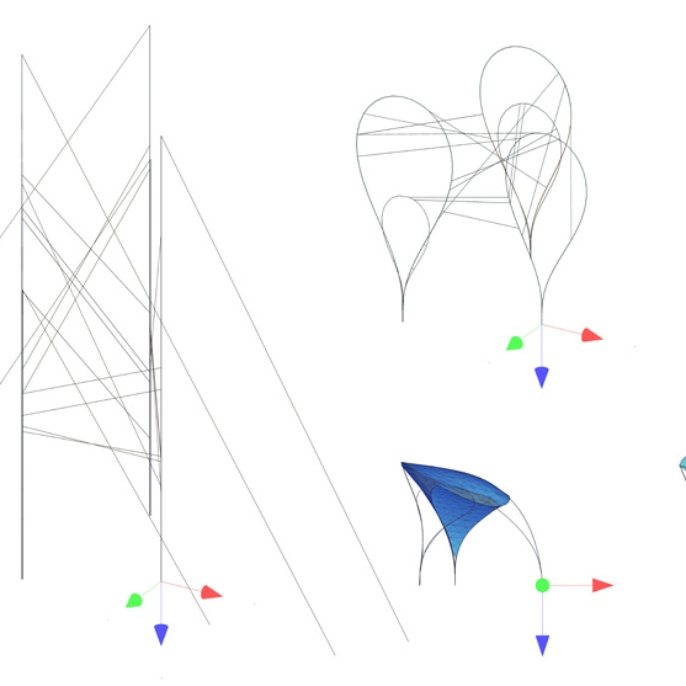

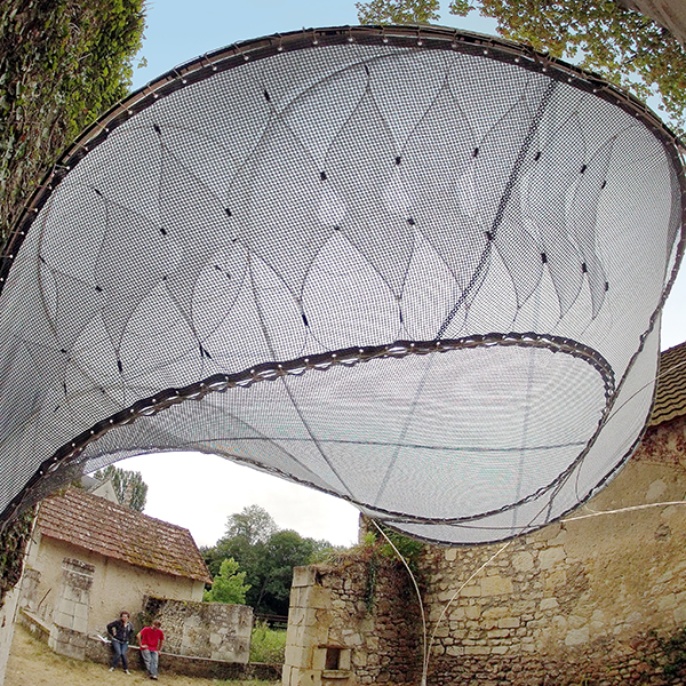

The Textile Hybrid M1 at La Tour de l’Architecte showcases combined research, with the students of the University of Stuttgart, on the subject of textile and bending-active material behavior for new typologies of lightweight structures being developed at the Institute for Computational Design (ICD) by Sean Ahlquist and Institute for Building Structures and Structural Design (ITKE) by Julian Lienhard. The Textile Hybrid M1 is situated at the historically protected site of a stone tower, built in the 1500’s, designed by Leonardo da Vinci in Monthoiron France. The innovative structural concepts of M1 are spatially and technically oriented to the design of a canopy whose exertion of force is minimal to the surrounding context, abutting buildings adjacent to the tower and staying clear of areas containing sensitive archaeological material. The longest span, of approx. 8 meters, provides cover to a region where one of the foundations for the tower’s stone buttresses sits. The minimal external structural exertion was accomplished, at multiple scales, through a macro-system of interwoven bending rods that form leaf-like shapes, and a meso-scale differentiated cell logic. The minimally invasive nature of the lightweight material system was a necessity given the delicate condition of the neighboring stone tower.

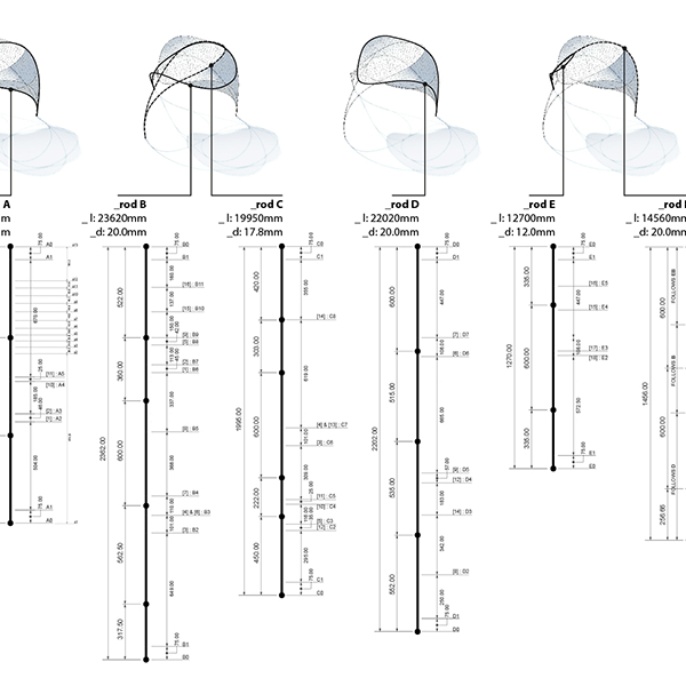

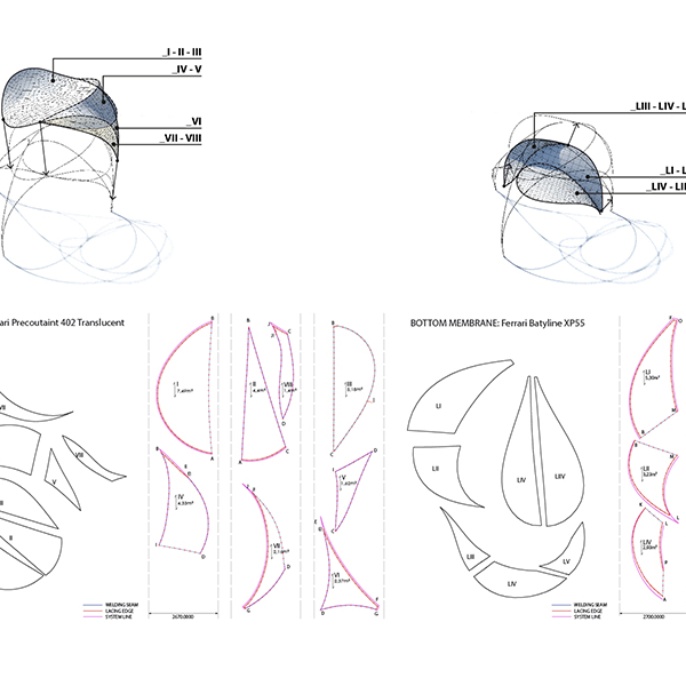

The morphology of the integrated material system is accomplished with glass-fibre reinforced polymer (GFRP) rods of diameters ranging from 3mm-24mm in combinations with textile membranes as continuous surfaces and open-weave meshes. The highly elastic rods gain their stiffness from active bending into curved leaf shaped modules which are networked into a global structural system. Stress stiffening effects are activated by further deformation of the system through the integration of a pre-stressed membrane surface, and thereby creating a fully textile hybrid system. The structure is comprised of 110 meters of GFRP rods, 45m² of membrane material covering an area of approx 20m² and anchored to the ground with only 3 foundations resting against the existing stone structures which neighbor the tower. In total, the building weighs approximately 60 kilograms (excluding foundations), with a clear spans ranging from 6 to 8 meters. Such high performance in the lightweight structure was reached by following a number of principal design rules found in most biological systems.

Scientific Development and project management:

Sean Ahlquist, Julian Lienhard

Concept Development:

David Cappo, Angel Pontes, Andreas Schoenbrunner

System Development, Building Design, Detail Design, Fabrication and Construction:

Markus Bernhard, David Cappo, Celeste Clayton, Oliver Kaertkemeyer, Hannah Kramer, Andreas Schoenbrunner

Funding:

DVA Stiftung

The Serge Ferrari Group

Esmery Caron Structures

“Studiengeld zurück”, University of Stuttgart

Additional material donations

CG Tec GmbH Carbon- und Glasfasertechnik (Carbonscout24)

Fibrolux GmbH

PENN Textile Solutions

Sika