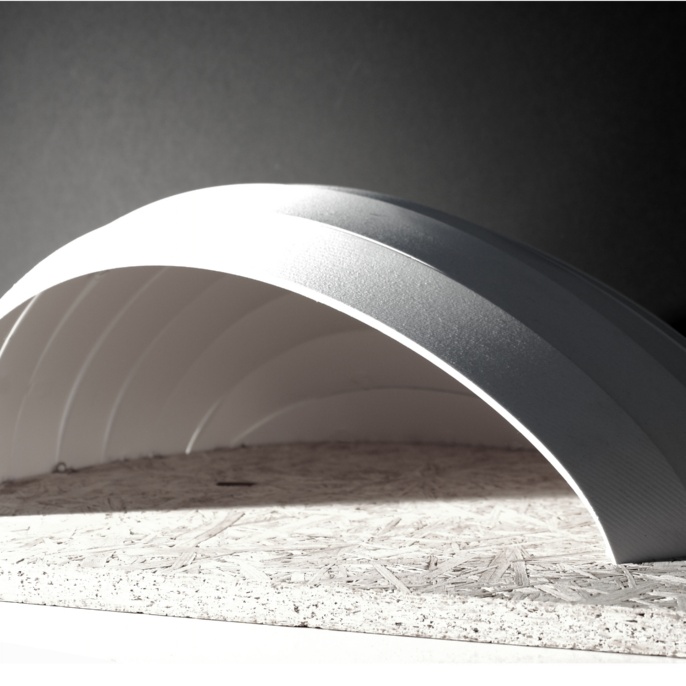

Bending-Active Segmented Shells

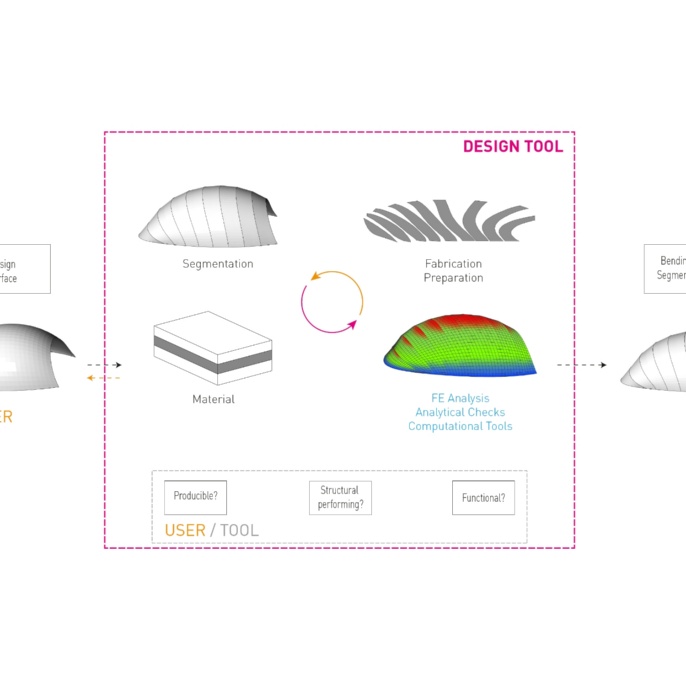

The presented Master Thesis aimed to develop a system and design process for Bending-Active Segmented Shells. Here, shell components are elastically bent and connected to form a shell structure. The research investigated the basic principles, materials and fabrication techniques as well as the structural behavior and possible design space of the developed system. This was the basis for the implementation of an integrative design and analysis tool in which parametric design and Finite-Element Analysis is combined.

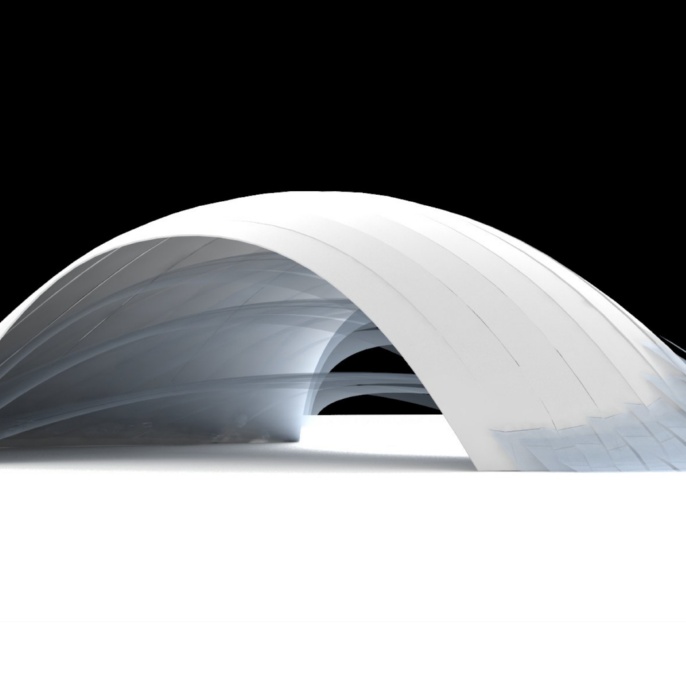

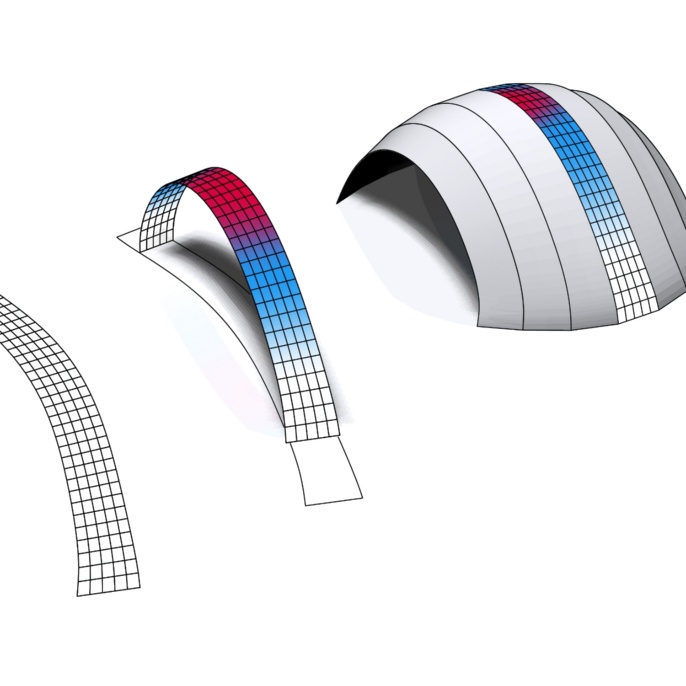

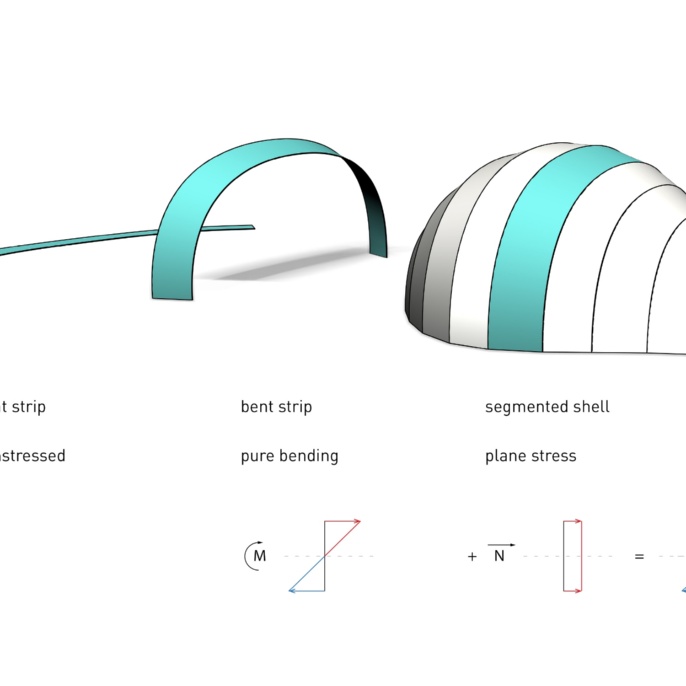

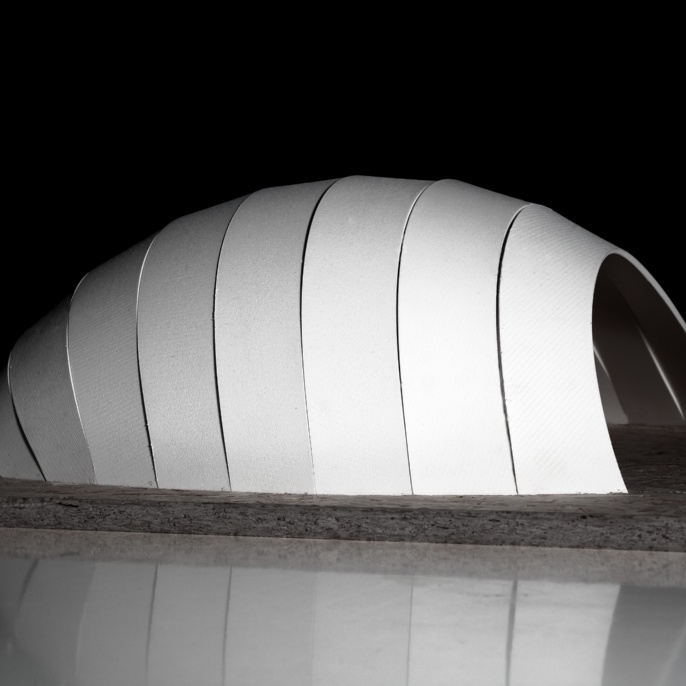

In general, bending-active structures show spatial, curved forms which are achieved by elastically bending initially flat or planar elements. This is advantageous because curved segments can be fabricated without extensive formwork or scaffolding.

The later connection of multiple bent strips allows to build continuous freeform shell structures with a very simple and economic construction. It has potential to reduce material usage, waste and labor compared to common construction methods for shells.

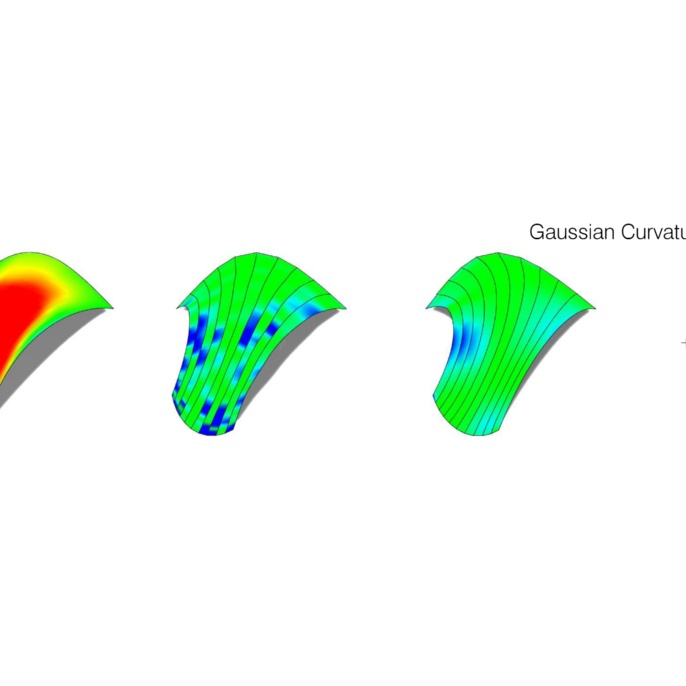

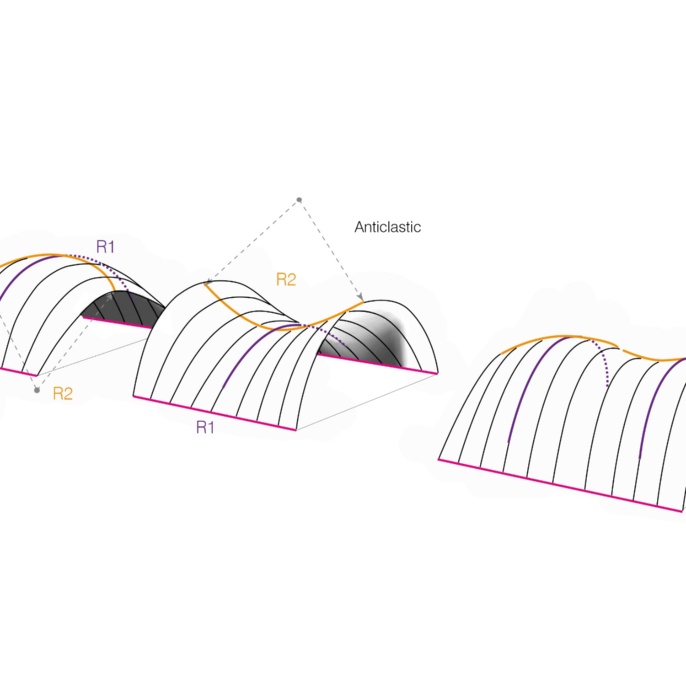

Due to the stresses from the bending process, the elements have to be comparatively thin and flexible. This results in a very low structural capacity of the single strips. By joining the segments to a double-curved shell surface, membrane action as the governing load bearing behavior is achieved and makes the system structurally very efficient.

Through the connection of the strips along their edges, different freeform geometries can be achieved.

The thesis shows that it is possible to build freeform shell structures only with the very simple process of active bending. No additional formwork is necessary. Through the efficient structural behavior of the shell, very filigree, thin and light structures can be designed. Simulations and analyses showed that the system has potential to be used in different building scales e.g. for facades or roofs. The initial production of the shell segments in a planar state makes their transport easier compared to spatial components. The elastic bending is reversible and allows for temporary constructions with multiple applications. Materials like wood or fiber-reinforced polymers have potential to be used for the shell segments because they show a high strength at a comparatively low Young’s modulus what allows small bending radii.

Contact: Jan Brütting

Institute of Building Structures and Structural Design – Prof. Dr.‐Ing. Jan Knippers

Institute of Computational Design and Construction – Prof. Achim Menges

Supervisors

Daniel Sonntag, Axel Körner