Photographs by ITECH/ICD/ITKE, University of Stuttgart

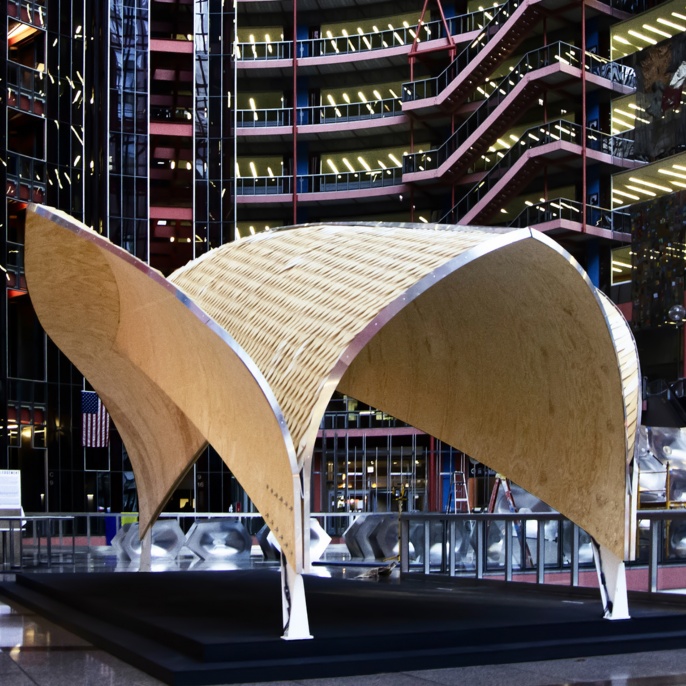

Photographs at Chicago Architectural Biennial (CAB) by ITECH/ICD/ITKE University of Stuttgart

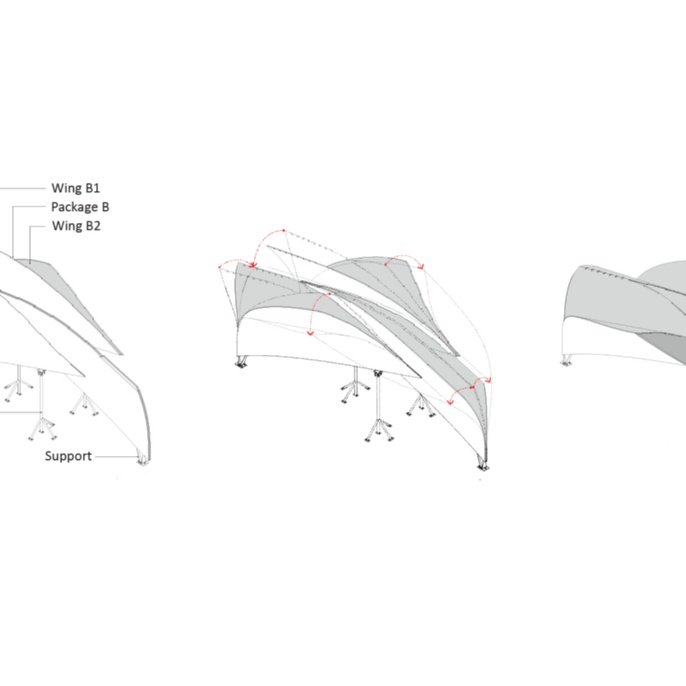

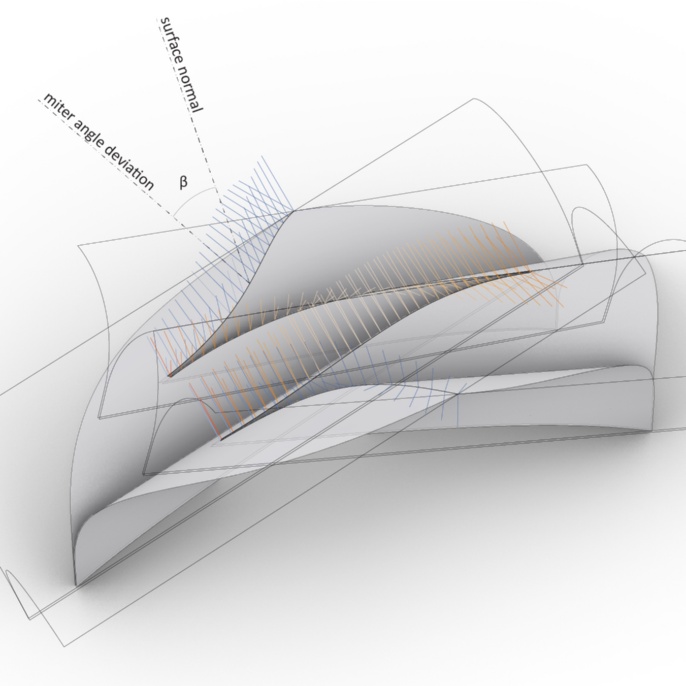

Diagrams by ITECH/ICD/ITKE University of Stuttgart

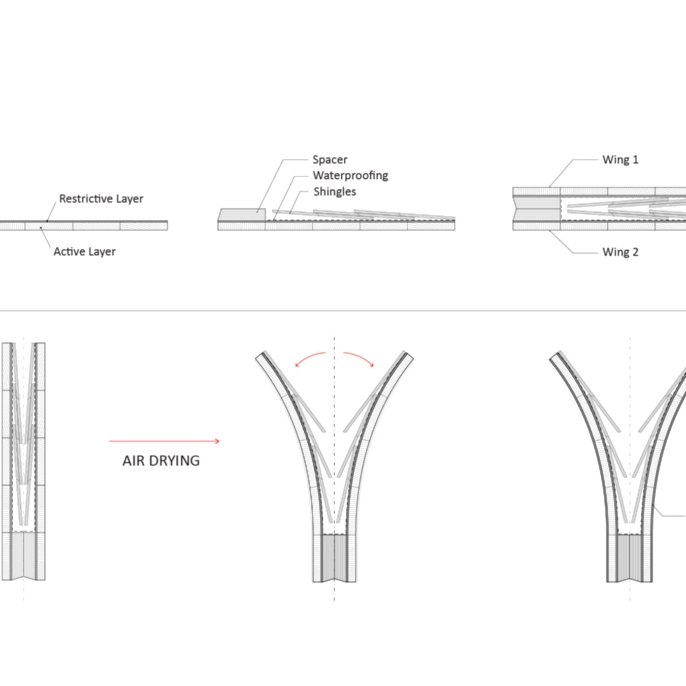

Prefabrication and Self-Construction Images by ITECH/ICD/ITKE University of Stuttgart

Insitu self-shaping of a lightweight form active wood structure

At the nexus of complex ecological, socioeconomic, and sociocultural crises, the built environment urgently requires a fundamentally new approach to design, engineering, and construction. As we shift from an era of energy abundance and industrial materials to one of energy scarcity and natural materials, material intelligence will become synonymous with construction logic. HygroShell, which makes its debut at the Chicago Architecture Biennial 2023, is at the forefront of this paradigm shift, harnessing the previously undesirable hygroscopic material properties of wood to create form and structure, exploring a new kind of bio-based and bio-inspired architecture.

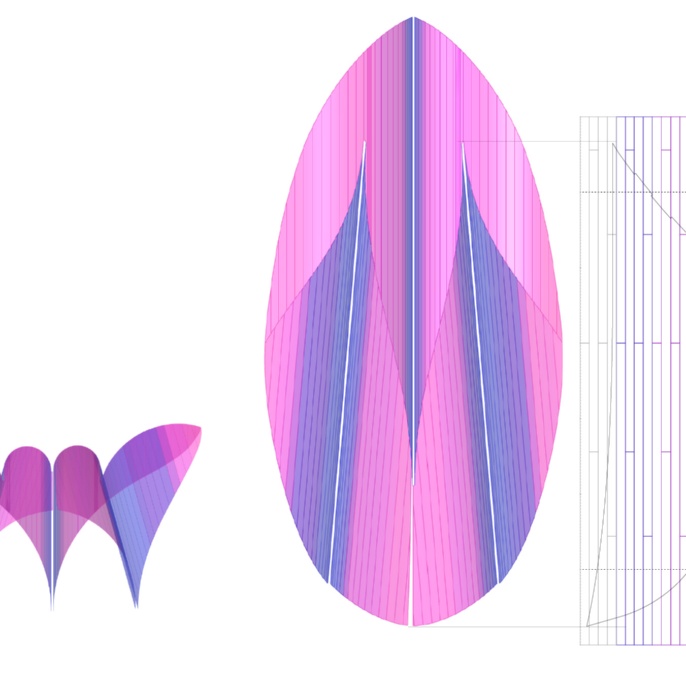

HygroShell investigates a first-of-its-kind, self-constructing-timber building system, heralding new material cultures in architecture. Utilizing novel computational methods to access timber’s inherent shape-changing properties, HygroShell showcases the design, engineering, and production of a full-scale, long-spanning, lightweight shell made from flat-packed, components curved in situ. Each component contains architectural, structural, and kinetic characteristics embedded into its flat state, actuating on site to produce a curved, shingle-clad, interlocked geometry.

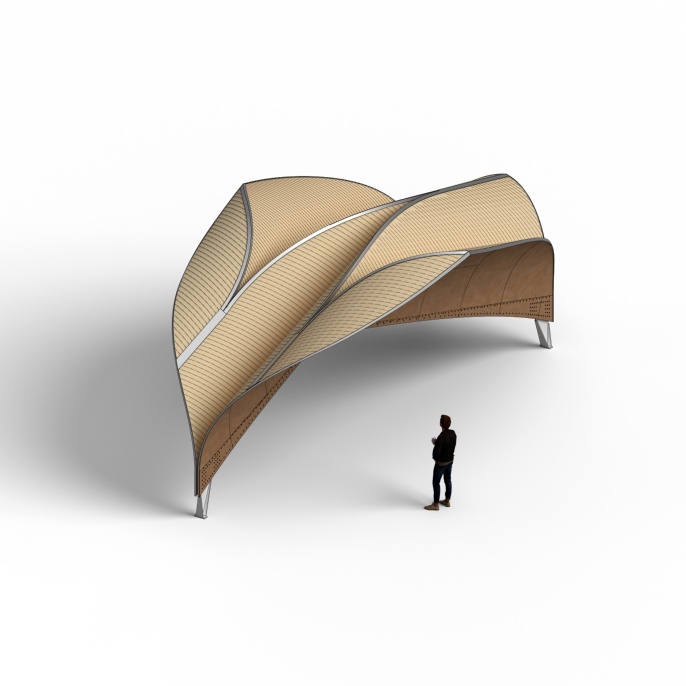

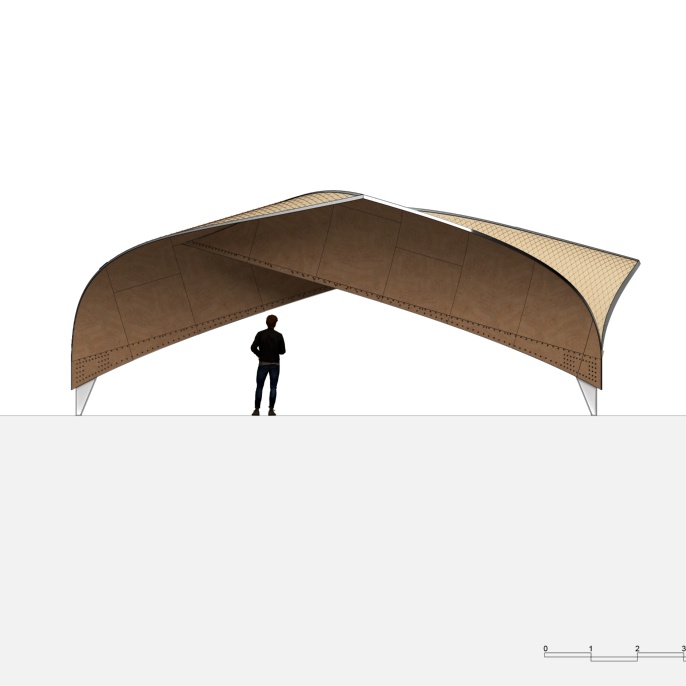

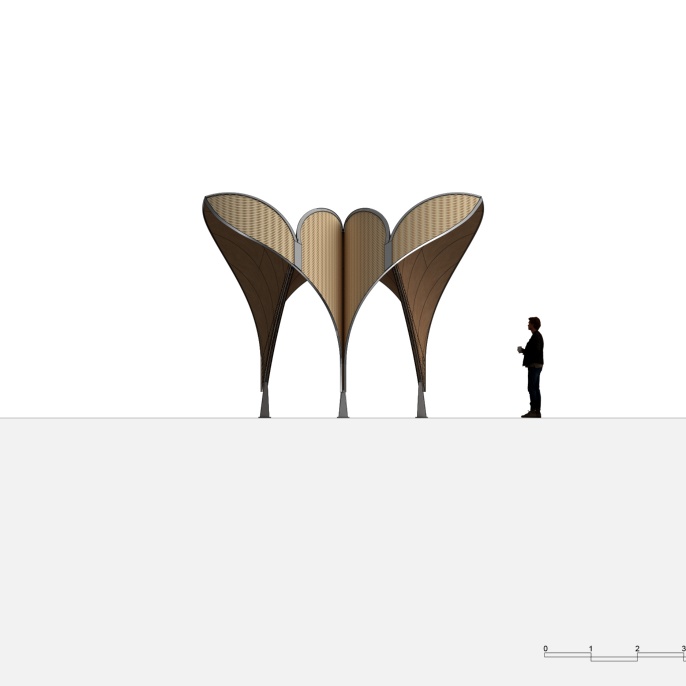

The result is a delicately arced canopy spanning 10 meters while only 28 millimeters thin. Diverging from typical structural typologies, the roof’s single-curved design unlocks new potentials for resource-saving, thin-shell construction with bio-based materials. HygroShell explores an alternative approach to future-proof architecture using the fundamental properties of timber as an in-situ shaping mechanism, structural driver, and design foundation. Through this computationally enabled understanding of natural materials, it is possible to achieve deeper architectural integration in both material and form, and to explore an ecologically effective, yet expressive material culture in architecture.

HygroShell was developed as a research pavilion within the context the ITECH Master’s program and the Cluster of Excellence Integrative Computational Design and Construction for Architecture (IntCDC), highlighting the importance and potentials of a cross-disciplinary and diverse research and educational environment.

Construction scale self-shaping through the hygromorphic properties of wood

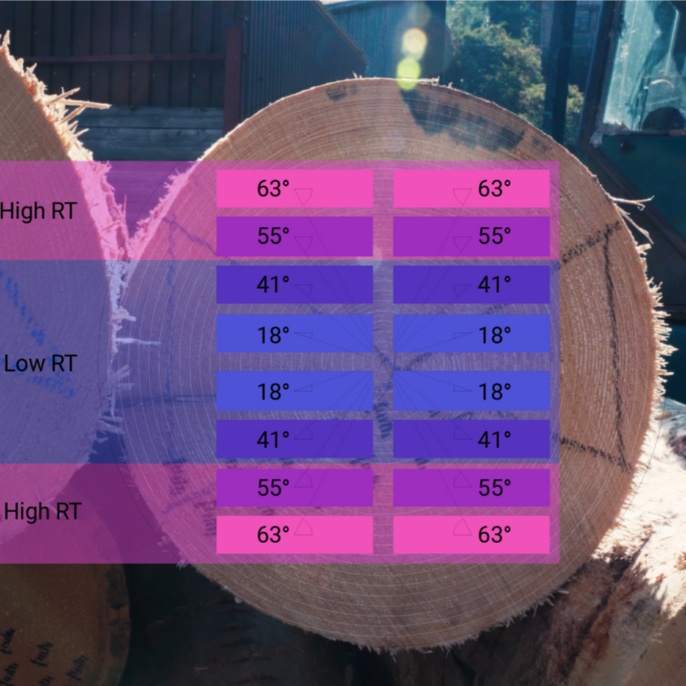

In recent years, there is a growing interest in using wood as a sustainable, regenerable building material, replacing materials with larger ecological footprints like steel and concrete. Historically, the strongly anisotropic hygroscopic properties of wood materials have been seen as a major drawback, leading to unwanted deformations or cracking and long term performance issues. When harvested, wood logs start with a high “green” moisture content and slowly begin to shrink as they dry out and equalize with the humidity of the surrounding air or through industrial kiln drying. HygroShell utilizes these hygromorphic properties by constructing bilayer, cross ply laminates with one thicker ’active’ layer starting with a high moisture content and one thinner ‘restrictive’ layer with low moisture content. The bilayer sheets curve when the wood in the active layer shrinks as it dries. Using analytically derived mechanical models, the natural properties of the material can be employed in a targeted way with precision, as a low energy, passive method of generating curved geometries. Compared to other smart shape changing materials, the strong anisotropy, structural characteristics, and general abundance of wood, make it ideal for integrating self-shaping economically, and at scales suitable for building construction.

Material driven computational design and manufacturing from sawmill to shell

Typical wood grading sorts boards into categories by structure and level of defect, generalizing variation and performance. Similarly, current modelling predictions and design opportunities for self-shaping wood are restricted by the specificity and accuracy of available material data. In contrast, HygroShell uses data representing material variation to drive the form, structure, and manufacturing process. A custom computational workflow was developed to integrate precise material information throughout the design and fabrication process. The approach integrates key parameters such as grain orientation and wood moisture content, that influence both the shaping process and the final structural integrity. Using an existing analytical method to predict curvature in self-shaping bilayers, an initial material informed design space representing the range of producible curvatures is created and visualized. From this a global parametric design framework was developed, considering the pavilion structure and shaping sequence. Working with industry partners, the design space was further adjusted to consider material efficiency, incorporating standard sawing patterns of the logs. Throughout the process manual data gathering, parametric detailing and direct structural modelling enables a material informed geometry and process.

The physical fabrication process begins with sawing spruce logs at the local sawmill and just in time for production, during which the moisture content is kept within a high range. Board-specific material information, including moisture content and grain orientation, is gathered and fed into the digital data model, allowing for simple high level understanding of each board's physical and mechanical properties. Every board in the stock is assigned a curvature potential which can be updated constantly based on its moisture content. Through this approach near real time, stock-specific arrangement of boards can be used to first optimize the global geometry with the available resources, and second, to match the variable curvature of the design to specific boards throughout the fabrication. This level of control allows variation in the material to be deployed intelligently to create design features, such as smooth transition in curvature across components and more structural favorable curvatures.

Material programming for next generation prefabrication

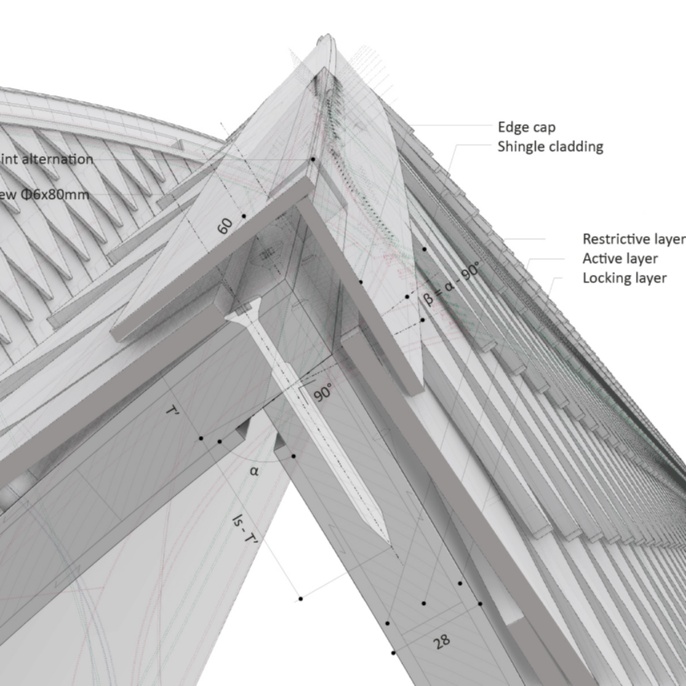

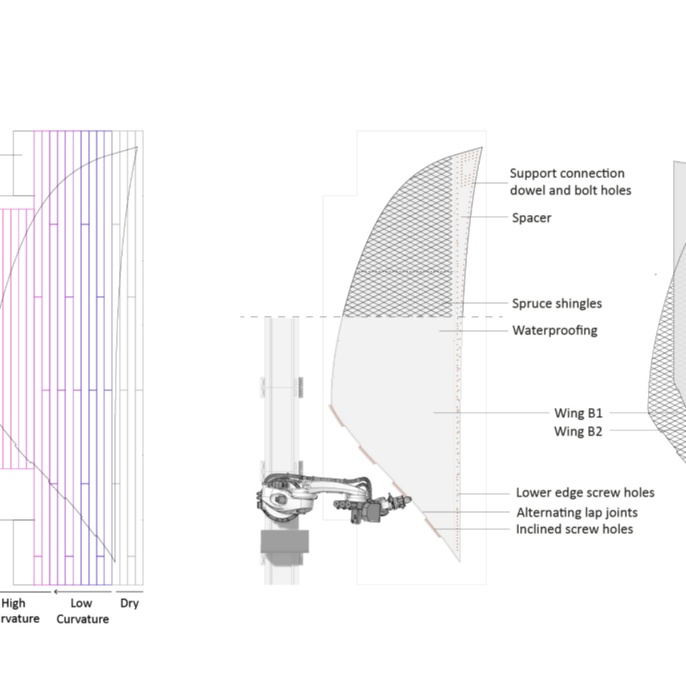

The defining aspect of HygroShell is the ability to embed physical shaping, structure, connection detailing, weather proofing and cladding, into flat layer based prefabrication. While traditional prefabrication methods in timber construction are limited to standardized panels, here material programming enables the advantages of flat panels in production with the advantages of surface active single-curved structures. Each of the 10.0 x 3.0 m wood bi-layer layups has been designed to be prefabricated flat on a table, using common timber manufacturing processes. Curvature is programmed using the digital workflow to select and place specific high moisture content boards, 20 mm thick, within the active layer that are glued to a thin, 4 mm plywood layer using a polyurethane adhesive and combination of French cleat pressing and vacuum lamination. Following lamination, a long format, curved finger joint connection and pre-drilled screw holes are derived from the curved geometry and machined into the bilayers using a 7-axis robotic milling setup. To minimize on-site effort on the later curved elements, a water-proofing layer and diamond shaped wood shingles (traditional in South Germany) are added in the controlled workshop environment. The shingles act like scales, adjusting to the surface curvature while maintaining weather protection. Groups of two components are then connected along a shared edge forming packages that are wrapped on their open faces to preserve their moisture during transport. Flat fabrication and assembly dramatically ease the manufacturing process without limiting the later geometric performance. The compact configuration of the packages minimizes the transport volume, requiring less than one truck to transport the packages to site, and simplifies onsite positioning.

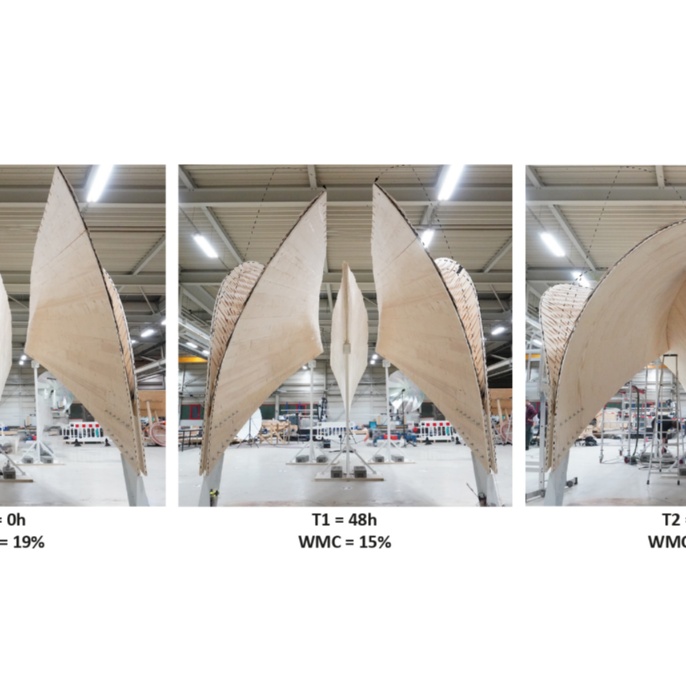

InSitu self-shaping and cyber physical monitoring for actuation uncertainty

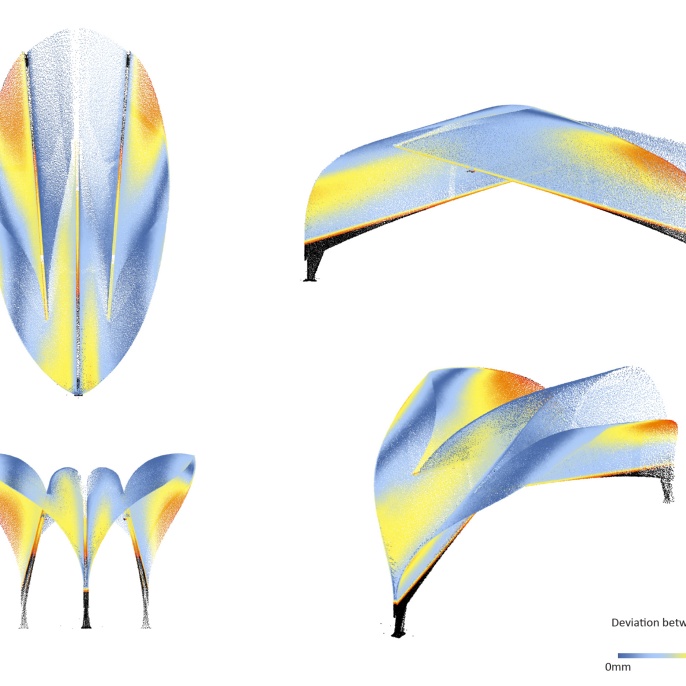

Onsite, the packages are positioned vertically and shape from flat to curved simply through air drying in an unconditioned environment. The shaping occurs passively without human interaction. Gradually, each component silently approaches its final curved geometry as the packages unfurl. A major challenge for self-shaping in situ arises from the natural variability of the relative humidity daily and seasonally. Rather than aiming for a perfectly coordinated shaping sequence, a cyber physical approach of monitoring curvature and moisture content was developed to assess the structure during shaping. A combination of iterative laser scanning and embedded IMU sensors were used to monitor the shaping over the 5 days of actuation in relation to the change in moisture within each component. As each component reached its final target, the longitudinal connections were fixed with screws and the geometry was locked by laminating an additional, elastically bent, 4 mm plywood layer to the inside of the curved bi-layers, locking the shape in place and increasing form stability. Through real time monitoring and strategic design of the connection detailing, it was possible to drastically reduce scaffolding, formwork and physical labor on site.

A lightweight surface active curved structure

HygroShell challenges the definition of existing structural typologies made of wood. Conventionally, structural use of curvature in timber structures has been viable mostly as a linear element but not as surface. Due to its high surface curvature, internal forces can be transferred principally through in-plane actions, making the structural system inherently scalable. Particular the surface intersections ensure the sound shell behavior and allows for longitudinal joinery without overall structural discontinuity. The geometric complexity in joinery and machining is mastered through parametric planning and digital fabrication. HygroShell demonstrates a new class of structural typology made only possible with intrinsic properties of wood and advanced digital planning, which enlightens further potential development in curved surface timber structures.

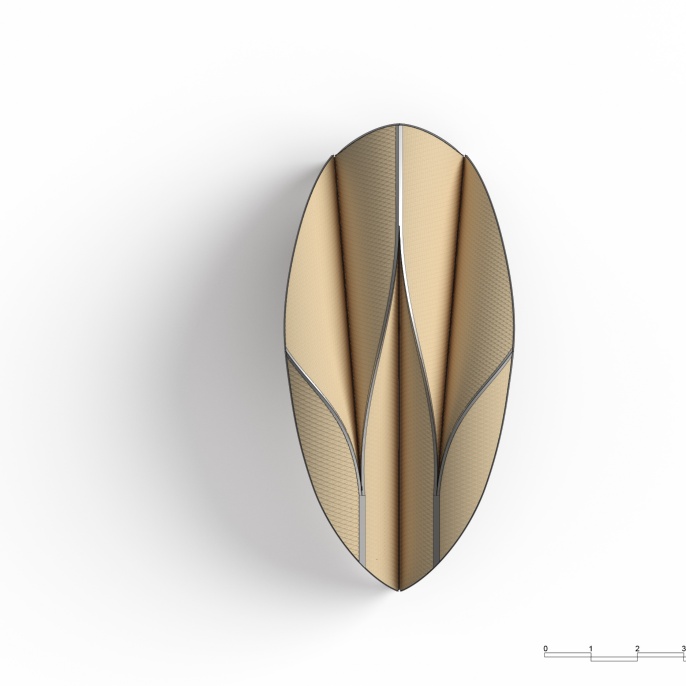

HygroShell was designed and engineered as a long spanning roof structure, going beyond what is possible with heavier typical timber components. The structure consists of a 9.5 m main span, consisting of intersecting arch-like vaults resting on three articulated supports. Utilizing an incredibly thin 28 mm of structural depth, the structure achieves a curvature-to-thickness ratio of 50-70:, and a slenderness ratio of 350:1 equivalent to that of eggshells, using only standard grade softwood materials. The structural system negotiates the cross section requirements for shaping and efficiency in material utilization, orienting major sectional stiffness from the dominant fiber direction in the primary loading direction. FEM models are used to verify the performance of the uniquely thin build ups and accurately evaluate the stability of the structure during the shaping process, including the impacts of self-weight on the achievable curvature and the loss of weight in drying. Instead of using mass as reinforcement, the lightweight system generates its stiffness through surface curvature and curved intersections. While optimized form often comes at the expense of materials and processing, HygroShell exhibits an extreme integration of form, material and manufacturing.

Material driven design for low impact sustainable construction

While mass timber construction is generally considered sustainable, from its core HygroShell presents a radical approach to further increase material performance and reduction of overall ecological impact. In timber construction, the kiln drying of wood from its initial high moisture content is by far the most energy intensive step in producing engineered timber products. Using relatively thin wood lamellas and air drying, a highly energy intensive manufacturing step is reduced while simultaneously gaining the shaping function of large, curved components. A combination of early industry involvement and investment in extreme process planning down to each board, ensures a maximum utilization of material resources and geometric form. Furthermore, the project emphasizes local sourcing of materials, reducing the impact of transportation. The primary structural wood is sourced from spruce trees harvested within 70 km of Stuttgart and the wood shingles originate from the region. Most prominently, the project points to the future potential to rethink the impact of onsite processes through a self-constructing buildings system. Not only does self-shaping eliminate the need for formwork, but its autonomy also has the potential to reduce the need for machines and labor on the construction site, aspects that are increasingly valuable in dense urban sites and sensitive environmental areas.

Integrative design and construction of a new class of long span timber architecture

HygroShell serves as a proof-of-concept, showcasing the possibilities of in situ self-shaping timber buildings system for simplified construction of long-spanning curved surface structures. As such it shifts the difficulty usually associated with the construction of curved surface structures from extensive formwork and complex machining towards an sophisticated pre-programming of the material itself. The design of the structure gives light to new possibilities for using timber in longer spanning structures without increasing the required material and structural mass. Covering an area of 40 m² with just 40kg/m² it is ultra light, physically and environmentally. Standing inside, the roof appears to float above, smoothly and effortlessly curving up from the three small supports where it touches the ground. The effect is highlighted by the smooth transition from vertical walls to arches to near horizontal cantilevers. The integrated connections are invisible from below creating a spatial continuity along the shallowly curving intersections, more familiar to concrete or textile architecture. From afar, the pavilion appears dynamic and paper thin, a synthesis of high tech formal language with the natural qualities of wood and the well-known vernacular of the wood shingling. The development of such concepts is only possible through the deep integration of computational design, simulation, material investigation and industry expertise, and highlights the potential of interdisciplinary research and education in architecture.

Fact list:

Building system:

Self-shaped curved wood bilayers (3 ply pine plywood – 4 mm, spruce wood – 20 mm, 3 ply pine plywood, cross laminated with 1K PUR) clad with a water-proof spacer mesh and spruce wood shingles.

Structural system:

Single curved timber shells with curved interlocking connections. Supported on 3 hinged supports

Technical Details:

Materials / sourcing, list companies

Span: 9.5 m longitudinal, 2.8 m transverse

Size (incl. base): 11 m length x 5.0 m width

Transport volume: 8.6 m x 3.7 m x 0.9 m

Covered Area: 40 m²

Supports: 3 articulated steel feet

Weight: 1400 kg (wood structure) 400 kg (shingles)

Material Quantities: 1.72 m³ wood, 0.69 m³ plywood, 16 kg glue, 7700 shingles

Time: 26 minutes log sawing, 10 days prefabrication, 4 days shaping

Project Team:

Institute for Computational Design and Construction – ICD

Dr.-Ing. Dylan Wood, Laura Kiesewetter, Prof. Achim Menges

Institute for Building Structures and Structural Design – ITKE

Dr.-Ing. Axel Körner, Kenryo Takahashi, Prof. Dr.-Ing. Jan Knippers

Concept Development, System Development, Fabrication & Construction

Andre Aymonod, Wai Man Chau, Min Deng, Fabian Eidner, Maxime Fouillat, Hussamaldeen Gomaa, Yara Karazi, Arindam Katoch, Oliver Moldow, Ioannis Moutevelis, Xi Peng, Yuxin Qiu, Alexander Reiner, Sarvenaz Sardari, Edgar Schefer, Selin Sevim, Ali Shokri, Sai Praneeth Singu, Xin Sun, Ivana Trifunovic, Alina Turean, Aaron Wagner, Chia-Yen Wu, Weiqi Xie, Shuangying Xu, Esra Yaman, and Pengfei Zhang

With support of: Katja Rinderspacher, Simon Bechert, Michael Schneider, Michael Preisack, Sven Hänzka, Sergej Klassen, Hendrik Köhler, Dennis Bartl, Sebastian Esser, Gregor Neubauer, Gabriel Kerekes and the Institute for Engineering Geodesy (IIGS)

Cluster of Excellence Integrative Computational Design and Construction for Architecture (IntCDC)

Project support:

German Research Foundation (DFG), University of Stuttgart, School of Talents – University of Stuttgart, Digitize Wood – Ministry of Rural Development and Consumer Protection Baden-Wuerttemberg (MLR), Zukunft Bau - Federal Ministry of Housing, Urban Development and Construction, Kolb Sägewerk, Henkel AG, Scantronic, Brookhuis Technologies, CAB5